What Is Lean Methodology And How Does It Work?

Discover what is lean methodology and see how its core principles eliminate waste to boost efficiency. Learn practical steps to transform your workflow today.

At its core, the lean methodology is a philosophy for maximizing customer value by relentlessly eliminating waste from your processes. It’s less a rigid set of rules and more of a mindset geared toward continuous improvement. This approach helps teams deliver better results with less friction, making sure every action counts.

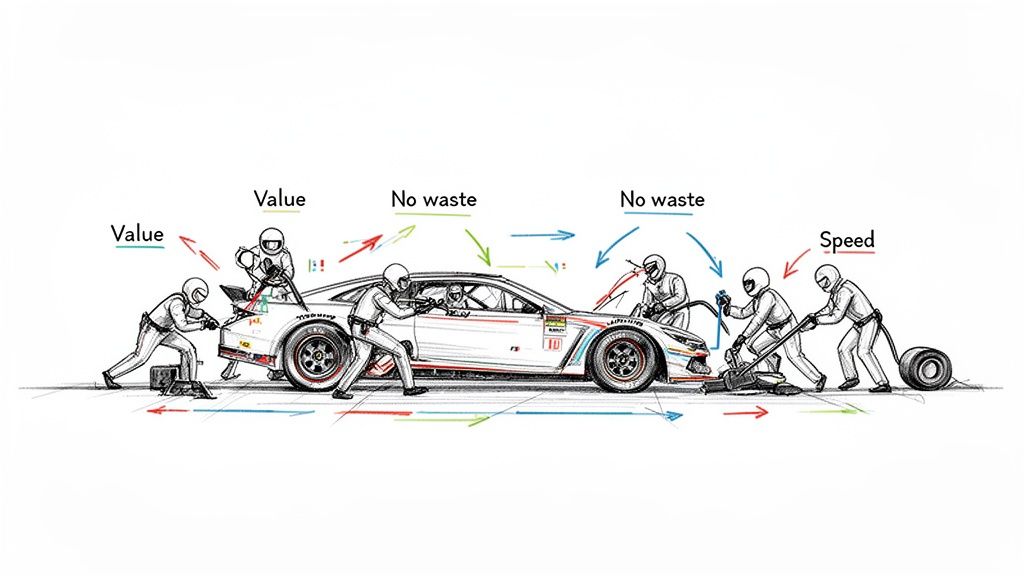

A Pit Crew Approach To Project Management

To really get what lean is all about, picture a high-performance pit crew during a race. Every single person has a specific job, and every action is precise, timed, and serves one purpose: getting that car back on the track faster. There are no wasted movements, no unnecessary tools lying around, and zero confusion.

That's the essence of lean. It applies those same principles of extreme efficiency to how a business runs, whether you’re developing software, managing a marketing campaign, or handling customer support. The goal is to strip away anything that doesn't add value from the customer's point of view.

Identifying And Eliminating Waste

In the business world, "waste" goes way beyond just physical materials. It’s anything that eats up resources—time, money, or effort—without creating something the customer actually cares about. This could be time sunk into pointless meetings, effort spent on rework because of unclear instructions, or delays from just waiting around for approvals.

By focusing on cutting out these inefficiencies, teams can dramatically improve their output. Adopting this mindset is the first step, and our guide on how to improve workplace efficiency offers practical strategies that fit perfectly with the lean philosophy. The real trick is to make spotting waste a team-wide habit.

The lean framework identifies eight common types of waste, often remembered by the acronym DOWNTIME. Giving these inefficiencies a name provides teams with a shared language to spot problems that are often hidden in the noise of daily work.

The 8 Wastes Of Lean You Can Eliminate Today

To help you get started, this table breaks down the "8 Wastes of Lean" with examples you’ll probably recognize from your own workplace. Recognizing these is the first step toward building a smoother, more effective workflow.

| Type Of Waste (Muda) | Description | Modern Workplace Example |

|---|---|---|

| Defects | Work that contains errors, needs to be redone, or fails to meet what the customer wanted. | Submitting a report with incorrect data that needs to be fixed and re-sent. |

| Overproduction | Creating more of something than is immediately needed by the next step or the customer. | Building dozens of software features that users never asked for or used. |

| Waiting | Idle time caused by delays, like waiting for approvals, information, or resources from another team. | A marketing team stuck waiting for legal approval before launching a campaign. |

| Non-Utilized Talent | Failing to use the skills, creativity, and knowledge of your team members effectively. | Ignoring great feedback from junior developers who are closest to the coding problems. |

| Transportation | The unnecessary movement of information, materials, or deliverables between teams or systems. | Endless email chains and handoffs just to get a simple task completed. |

| Inventory | Having too much work-in-progress (WIP), unfinished projects, or raw materials stockpiled. | A backlog with 100 unstarted tasks that clogs up the project management system. |

| Motion | Unnecessary movement by people, such as constantly searching for files or switching between apps. | Toggling between your email, tasks, and CRM just to find basic customer info. |

| Extra-Processing | Doing work that adds no real value, often by using overly complex tools or convoluted processes. | Requiring three levels of management sign-off for a minor office supply expense. |

Once you start looking for these eight wastes, you'll see them everywhere. The good news is that every piece of waste you find is an opportunity to make things better, faster, and more valuable for your customers.

The Surprising History Of Lean From Shipyards To Software

The lean methodology might seem like the latest business buzzword, but its roots run deep—centuries deep, in fact. Its principles aren't just abstract theories; they're battle-tested concepts born from real-world problems and the need to do more with less. Looking back at this history shows just how timeless and adaptable these ideas really are.

Believe it or not, the journey starts long before the first factory floor. You can find early glimpses of lean thinking way back in the 1400s at the Venetian Arsenal, where shipbuilders created one of the world’s first assembly lines. By organizing the construction of galley ships along a canal, they could build an entire vessel in a single day—a mind-boggling feat of efficiency that hinged on standardized parts and a continuous workflow.

The Rise Of Mass Production

Fast forward a few centuries, and the industrial revolution was setting the stage for the next big leap. In 1913, Henry Ford famously combined the ideas of interchangeable parts with a continuous-flow assembly line at his Highland Park plant. The impact was nothing short of revolutionary.

Suddenly, the time it took to build a Model T dropped from over 12 hours to just 93 minutes per vehicle. This was a staggering 93% reduction in manufacturing time, making cars affordable for the average family and proving the immense power of a well-designed system. By 1927, Ford had produced over 15 million Model T cars. But Ford's system had a catch: it was brilliant at churning out identical products in huge volumes but stumbled when it came to flexibility.

Toyota And The Birth Of The Lean System

The true birth of what we now call lean happened in post-WWII Japan. Facing crippling resource shortages—no cash, no space, no materials—Toyota couldn't just copy Ford’s mass-production playbook. They needed a system that was not only efficient but also nimble enough to produce different types of vehicles in small batches.

This challenge pushed innovators like Kiichiro Toyoda and Taiichi Ohno to create the Toyota Production System (TPS). They found inspiration in an unlikely place: American supermarkets. This led to a "pull" system where parts were supplied Just-In-Time (JIT), right as they were needed, instead of being stockpiled in massive, costly inventories. This approach didn't just save space and money; it made production problems instantly visible. TPS was built from the ground up to eliminate waste in all its forms, an idea born directly from the tough times they faced. For a deeper dive into these historical roots, you can discover more insights about the evolution of lean efficiency on Leandemy.com.

At its core, the Toyota Production System was an answer to a simple question: "How can we provide the highest quality, at the lowest cost, with the shortest lead time?" The answer was found by systematically removing anything that did not add value for the customer.

This relentless drive for improvement sparked other breakthroughs, like Single-Minute Exchange of Die (SMED), which dramatically slashed the time needed to switch manufacturing equipment between products. By the 1970s, setup times that once took hours were down to just three minutes.

From Venetian shipyards to Japanese car plants, this history shows that lean is, at its heart, just smart problem-solving. It’s a lesson that's just as relevant for today’s software teams and project managers as it was for car manufacturers a century ago.

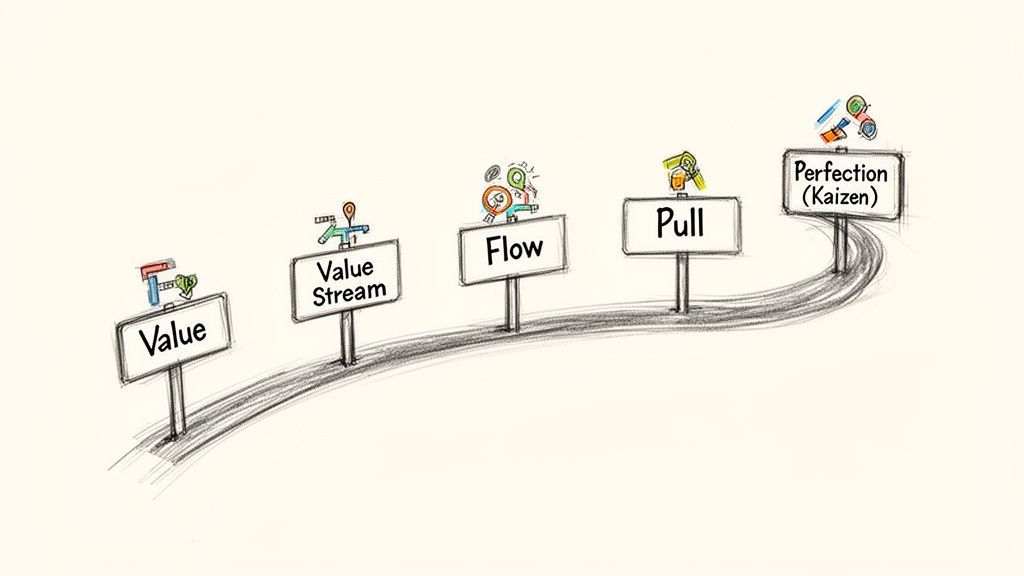

The Five Core Principles That Drive Lean Success

To really get what Lean is all about, you have to understand the five core principles that make it tick. These aren't just buzzwords; they're a step-by-step roadmap for completely rethinking how you work. Follow this framework, and any team can start systematically cutting out the noise and zeroing in on what truly matters to the customer.

Each principle builds on the one before it, kicking off a powerful cycle of improvement that just keeps going. Let's break down each one to see how it works in the real world.

1. Define What Your Customer Values

First things first: you have to define Value, and it has to be from your customer's point of view. It’s all too easy to think you know what's valuable, but Lean forces you to ask one simple, tough question: what is the customer actually willing to pay for? Everything else is just noise.

This means value isn't about how much effort your team put in, how complex a feature is, or what you think is cool. It’s defined entirely by what the end user needs, right here, right now, at a specific price.

Imagine a software team spends months cranking out a dozen new features. If their customers only really needed one of them to solve a burning problem, all the time and energy spent on the other eleven was waste. Getting value right is the compass that guides every other decision.

2. Map The Entire Value Stream

Once you've nailed down what value means to your customer, the next move is to map the Value Stream. This is the entire journey, from the initial idea all the way to getting it in the customer's hands. Every single action, handoff, and piece of information is part of it.

Think of it like planning a road trip. You don't just stare at the destination; you map the entire route, noting every turn, potential traffic jam, and pointless detour. The whole point of value stream mapping is to make your entire process visible.

This forces you to sort every activity into one of three buckets:

- Value-Adding Steps: These are the actions that directly build the thing your customer wants.

- Non-Value-Adding but Necessary Steps: Stuff you have to do because of regulations or current tech, even if the customer doesn't care.

- Waste: Anything that eats up time and resources without adding a shred of value for the customer.

By laying it all out, teams can finally see where the real bottlenecks and wasteful habits are hiding. It’s often a huge eye-opener.

3. Create A Smooth And Uninterrupted Flow

With your value stream mapped and the waste identified, the third principle is all about creating Flow. The goal is simple: make sure work moves smoothly through your process without hitting roadblocks, interruptions, or long queues. In a perfect Lean world, once a task starts, it doesn't stop until it's done.

This is the exact opposite of the old "batch-and-queue" method, where work just piles up at every stage. Flow is about knocking down the walls between teams and killing the "wait time" that crushes productivity. When you get it right, work glides from one step to the next, just like a river. And when you achieve flow, the time it takes to get from start to finish shrinks dramatically.

"Flow is the smooth, uninterrupted movement of work through the value stream. When flow improves, lead times shorten, problems become visible sooner, and quality improves."

4. Establish A Pull-Based System

The fourth principle, Pull, is what makes this smooth flow sustainable by tying it directly to customer demand. Instead of a "push" system—where you make a bunch of stuff based on a forecast and then try to push it onto the next team or the customer—a pull system flips the script.

Nothing gets made until the customer (or the next person in the process) asks for it. This "just-in-time" approach kills overproduction, one of the biggest forms of waste. It keeps the amount of work-in-progress (WIP) to a minimum and guarantees the team is only working on things that are needed right now. For instance, a content team using pull would only write an article after a specific audience need has been prioritized, not just build a library of content that might go unread. To do this right, teams need to know how to pick what to pull next, which makes having solid prioritization techniques essential.

5. Pursue Perfection Through Continuous Improvement

The final principle is Perfection, better known as Kaizen (the Japanese term for "continuous improvement"). This isn't about reaching some flawless end state. It's about committing to a culture of always getting better, every single day.

It’s about making the first four principles a daily habit—constantly re-evaluating value, tweaking the value stream, smoothing out the flow, and refining the pull system. This mindset empowers everyone on the team to spot problems and fix them at the root. Through small, consistent, incremental changes, an organization can achieve incredible results and build a culture where improvement is truly everyone's job.

How Lean Really Changes the Game in Business

Adopting the lean methodology isn't just about shuffling tasks around on a board. It's a total mindset shift that gives a modern business real, tangible advantages. When teams truly get into a lean groove, they stop just doing tasks and start building a powerful engine for growth, quality, and resilience. The benefits are felt everywhere, from the company's bottom line all the way to employee morale.

Think about a customer support team completely buried in tickets. The "before" picture is pure chaos: it takes days to resolve anything, customers are fuming, and the support agents are burning out from endless handoffs and digging for information.

But after they adopt lean principles, everything changes. The team maps out their entire process—the value stream—and starts spotting all the waste, like pointless approval steps or time wasted jumping between different systems.

The "after" picture? A world of difference. By cutting out those wasteful handoffs and giving agents the right information when they need it, the team takes ticket resolution times from days down to just a few hours. This isn't just about moving faster; it's about delivering way more value.

Strategic Wins That Go Way Beyond Efficiency

The true magic of lean is in the strategic outcomes it produces. Sure, getting more efficient is great, but the ripple effects are what really give you a killer competitive edge.

- Better Products and Services: By obsessively hunting down defects and fixing the root cause of errors, quality becomes part of the process itself, not just a final check. This means fewer mistakes, less rework, and a much better end product for the customer.

- Happier Customers: Lean is all about customer value. When every single process is fine-tuned to give the customer what they want, when they want it, satisfaction naturally goes through the roof. They get better products, faster—and that builds serious loyalty.

- A More Engaged, Proactive Team: Lean trusts the people doing the work to improve it. When you give employees the tools and freedom to solve problems, their engagement and job satisfaction skyrocket. They go from being cogs in a machine to active owners of their work.

For startups, applying these same principles to test a business idea is a game-changer. Understanding what a Lean Canvas entails helps you apply that waste-reduction mindset to the business model itself, making sure you're building something people actually want before you sink a ton of time and money into it.

The Proof Is in the Numbers (and the Culture)

The term 'Lean' was officially coined back in 1988 by John Krafcik. His research showed how Toyota’s Production System absolutely crushed traditional mass production methods. This thinking exploded in popularity with the 1990 book The Machine That Changed the World. It found that Japanese lean plants built cars in half the time using 50% less effort and 40% less capital investment, while their productivity growth was double their competitors'.

This isn't just history; it's proof that lean delivers real, measurable results. It's the same principle that helps today's small businesses using Google Workspace boost their sales productivity by 40% when they integrate tools like Kanban Tasks and a unified CRM.

At the end of the day, lean isn't just about being faster or cheaper. It's about building a resilient organization with a culture of continuous improvement, where every person on the team feels empowered to make things better, every single day.

Ultimately, lean transforms a business by building a system that’s designed to learn and adapt. By focusing on concrete outcomes—like shorter lead times, fewer defects, and higher team engagement—it makes an undeniable case for why this is a powerful strategy for long-term growth, not just a quick fix for efficiency.

Putting Lean Into Practice With Kanban Boards

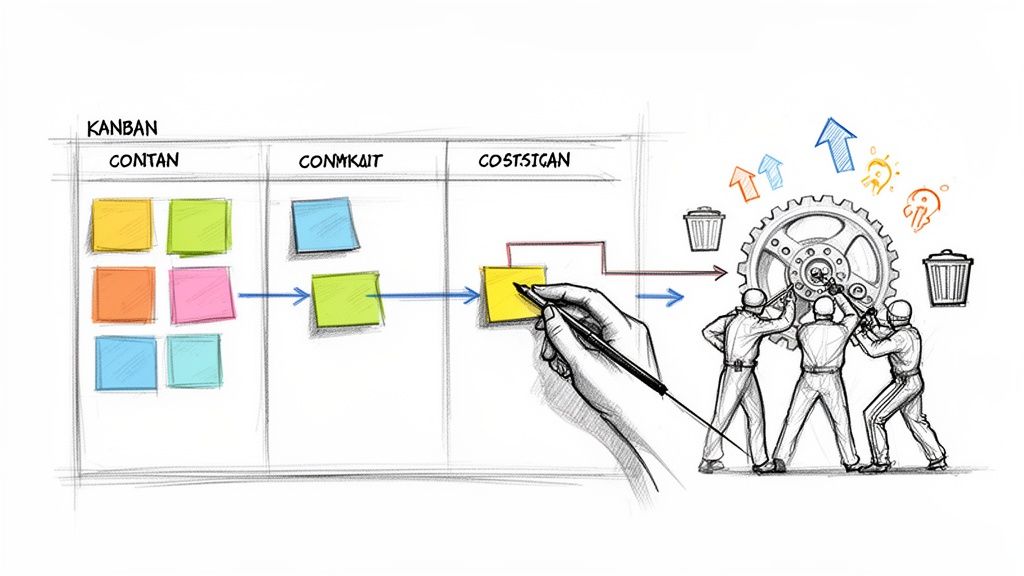

Knowing the principles of Lean is one thing, but actually putting them to work is where the magic happens. For most teams, one of the simplest yet most powerful tools to make Lean a daily reality is the Kanban board. It’s so much more than just a wall of sticky notes; it's a visual system designed to help you see your workflow, smooth out the bumps, and stop the bottlenecks that grind productivity to a halt.

At its core, a Kanban board is a direct translation of Lean ideas into a hands-on, visual format. It lets any team instantly see their entire Value Stream (the journey from a request to a finished product), manage the Flow of work, and create a Pull system by limiting how much work is in progress at once. This makes it the perfect launchpad for any team wanting to get Lean.

Visualizing Your Workflow With Kanban

The first and most powerful thing a Kanban board does is make your work visible. Suddenly, tasks aren't buried in email chains or scattered across different documents. Every single piece of work gets its own card on a shared board for everyone to see. This simple act is a massive first step in spotting and eliminating waste.

For example, a typical Kanban board for a new marketing campaign might have a few key columns:

- Backlog: A parking lot for all the ideas and potential tasks that haven't been given the green light.

- To Do: Approved tasks that are officially in the queue and ready to be started.

- In Progress: What the team is actively working on right now.

- In Review: Work that's finished but needs a second pair of eyes for approval or a quality check.

- Done: Completed tasks that have delivered their value.

This clear, shared picture means everyone knows the status of every task with just a glance. It immediately shines a spotlight on where work is piling up or where a teammate might need a hand.

This journey of getting Lean is a continuous cycle. You find the waste, optimize how you work, and deliver more value to your customers. It's a simple but powerful flow.

As the diagram shows, Lean isn't a one-and-done project. It’s a habit of continuous improvement, and a Kanban board is the perfect tool to support that habit.

Implementing Flow and Pull With WIP Limits

One of the secret weapons of a real Kanban system is the Work-in-Progress (WIP) limit. A WIP limit is just a rule that caps how many tasks can be in a certain column at the same time. For instance, you could decide your "In Progress" column can only have three tasks in it. No more.

This simple constraint is incredibly powerful. It forces the team to finish what they've started before pulling new work in, which is the very essence of a Pull system.

By setting WIP limits, teams stop starting new work and start finishing existing work. This simple constraint is the key to creating a smooth, predictable flow and preventing the team from being overwhelmed by too many active tasks.

When a column hits its WIP limit, no new cards can be added until something moves out. This naturally discourages multitasking—a huge productivity killer—and encourages team members to collaborate and clear bottlenecks together. If a card is stuck, the whole team can jump in to solve the problem, keeping the entire system moving forward.

For teams already using Google Workspace, learning how to create a free Kanban board on Google using Kanban Tasks is a great way to start experimenting with these powerful WIP limits.

A Practical Example: A Marketing Campaign

Let's see how this works in the real world. Imagine a marketing team using a Kanban board for a new product launch. They have the columns we talked about earlier, and they've set a WIP limit of two for their "In Progress" column. Only two big tasks at a time.

The content writer finishes a blog post and moves its card to "In Review." At the same time, the graphic designer is still creating the social media assets, which means the "In Progress" column is still at its limit of two.

Instead of just grabbing another task from the "To Do" list and starting something new, the content writer sees the situation on the board. They can't pull a new task, so they help out by reviewing the social media copy to help move that card along.

This small, natural act, guided by the visual cues of the Kanban board, is Lean in action. It cuts down on "waiting" waste, makes better use of everyone's skills, and keeps work flowing steadily. The team isn't working harder; they're working smarter, focused on finishing things together and delivering real value.

Common Misconceptions About The Lean Approach

To really get on board with the lean methodology, we first need to bust a few myths. These misconceptions often pop up and cause a lot of unnecessary confusion and resistance, painting Lean as some kind of harsh, robotic system.

The truth is, it's a philosophy centered on people, designed to make work better for everyone involved. Let's clear the air and debunk the most common myths.

Myth 1: Lean Is Just For Manufacturing

This is probably the biggest misunderstanding out there. While it’s true that Lean’s modern roots are in the Toyota Production System, its principles are completely universal. At its core, Lean is about finding what creates value and getting rid of everything that doesn't.

That concept works just as well for writing code, processing invoices, or running a marketing campaign as it does on a factory floor. Today, you'll find Lean being used successfully in just about every industry you can think of—healthcare, software development, finance, even government. The "product" might be different, but the goal of delivering value to a customer is always the same.

Myth 2: Lean Is A Code Word For Downsizing

This one is not only wrong, it’s damaging. Lean is about cutting out wasteful activities, not people. When you improve a process and make it more efficient, you’re actually freeing up your team's time and mental space from tedious, low-impact tasks.

This lets them shift their focus to more creative, strategic work—the kind of stuff that actually drives innovation and growth. A true Lean culture sees its employees as the most valuable resource, because they're the ones on the ground who have the insights to make things better.

Lean doesn't ask, "Who can we get rid of?" It asks, "How can we remove the frustrating obstacles that prevent our talented people from doing their best work?" This shift in perspective is key to its success.

Myth 3: Lean Means Working Faster And Harder

A lot of people hear "lean" and think "burnout." This myth confuses being busy with being productive. Lean isn't about cracking a whip and pushing people to work at a frantic, unsustainable pace. It's the complete opposite.

The whole point is to create a smooth, predictable workflow by getting rid of the very things that force people to rush, cut corners, or multitask. By eliminating waste—like waiting around for an approval, hunting for a missing file, or redoing sloppy work—Lean actually creates a calmer, more focused work environment. It’s all about working smarter, not harder, to get better results with way less stress.

Got Questions About Lean? We've Got Answers.

As teams start digging into what lean methodology is all about, a few common questions always seem to pop up. Getting straight answers can give you the confidence to start applying these principles without getting lost in the theory.

Let's clear up some of the most frequent questions we hear from teams who are just getting their feet wet.

What Is The Real Difference Between Lean And Agile?

This one comes up all the time, and it's a great question since both are so popular. Here’s a simple way to think about it: Lean is the "why," and Agile is often the "how."

Lean is a big-picture philosophy. It’s all about creating the most value for the customer by relentlessly cutting out waste from your processes. Agile, on the other hand, is a specific playbook—a set of practices, especially common in software development, that helps teams deliver work in small, quick cycles.

They aren't rival ideas; in fact, they work beautifully together. An Agile team is naturally practicing Lean principles every day by avoiding overproduction and focusing on shipping valuable work fast.

How Can A Small Team Start Using Lean Without A Big Budget?

Lean is a mindset first, a toolset second. You absolutely don't need expensive consultants or fancy software to get started. Some of the most powerful lean practices are completely free and can be put into action tomorrow.

- Daily Stand-Up Meetings: Kick off the day with a quick, 15-minute check-in. What did you do yesterday? What’s the plan for today? Any roadblocks? This simple habit gets problems out in the open instantly and keeps work flowing.

- Create a Simple Kanban Board: Grab a whiteboard and some sticky notes, or use a free digital tool. Just visualizing your workflow will immediately shine a light on bottlenecks you never even knew you had.

- Ask "Why?" Five Times: When something goes wrong, don't just patch the problem. Ask "why" it happened, then ask "why" to that answer, and so on, about five times. This is a classic technique for digging past the symptoms to find the real root cause.

The biggest first steps in Lean are about changing habits, not buying tools. It’s a culture shift that starts with simple, consistent actions focused on spotting and removing obstacles in your daily work.

What Is The First Step To Identifying Waste In My Workflow?

The best place to begin is with a simple, personal audit. You don't need to jump into a complex value stream mapping exercise right away. Just pick a single, common task you do all the time—like putting together a weekly report or onboarding a new client—and mentally walk through it step-by-step.

For each step, ask yourself a few direct questions:

- Does this step actually add value for the customer? (Seriously, would they care if we skipped it?)

- How much time is spent just waiting around? (e.g., waiting for an approval or for data from another department)

- Is there any rework involved? (Do I often have to go back and fix mistakes from an earlier step?)

This quick self-audit will immediately highlight different types of waste—like waiting, defects, or unnecessary steps—giving you a clear, actionable place to start making things better.

Ready to put these Lean principles into practice without leaving your inbox? With Tooling Studio, you can transform your Gmail into a powerful, collaborative Kanban board. Start visualizing your workflow, eliminating waste, and improving your team's flow today. Get started for free at tooling.studio.